Optimizing the Efficiency of Biomass Pyrolysis

The pyrolysis process plays a critical role in the conversion of biomass into valuable products, such as biochar, bio-oil, and syngas. It involves heating organic material in the absence of oxygen, facilitating the breakdown of complex hydrocarbons into simpler compounds. While pyrolysis technology has been around for decades, achieving high efficiency in biomass conversion remains a significant challenge. Factors such as feedstock composition, reactor design, energy management, and operational control can dramatically influence the yield and quality of the final products. Optimizing these parameters in a pyrolysis plant can enhance efficiency, improve output, and reduce operational costs.

Feedstock Pre-treatment and Moisture Control

Feedstock composition is one of the most important factors affecting the efficiency of biomass pyrolysis. Biomass materials, such as wood, agricultural residues, or algae, typically contain significant moisture levels, which can inhibit the thermal decomposition process. High moisture content requires additional energy to evaporate water before pyrolysis can occur, which reduces overall efficiency.

-

Drying: Moisture content must be reduced to an optimal level, typically below 15%, to ensure that energy is used primarily for pyrolysis rather than moisture evaporation. Pre-drying techniques such as air-drying or mechanical dryers can help prepare the feedstock for efficient pyrolysis. Drying biomass before entering the pyrolysis plant minimizes energy wastage, increases the heating rate, and enhances the yield of biochar and bio-oil.

-

Size Reduction: Biomass feedstock often needs to be reduced in size to facilitate uniform heating and better heat transfer. Smaller particles allow for quicker and more uniform thermal decomposition, thus improving both the speed and efficiency of biochar machine. Optimal particle size also aids in maximizing surface area, which enhances heat absorption.

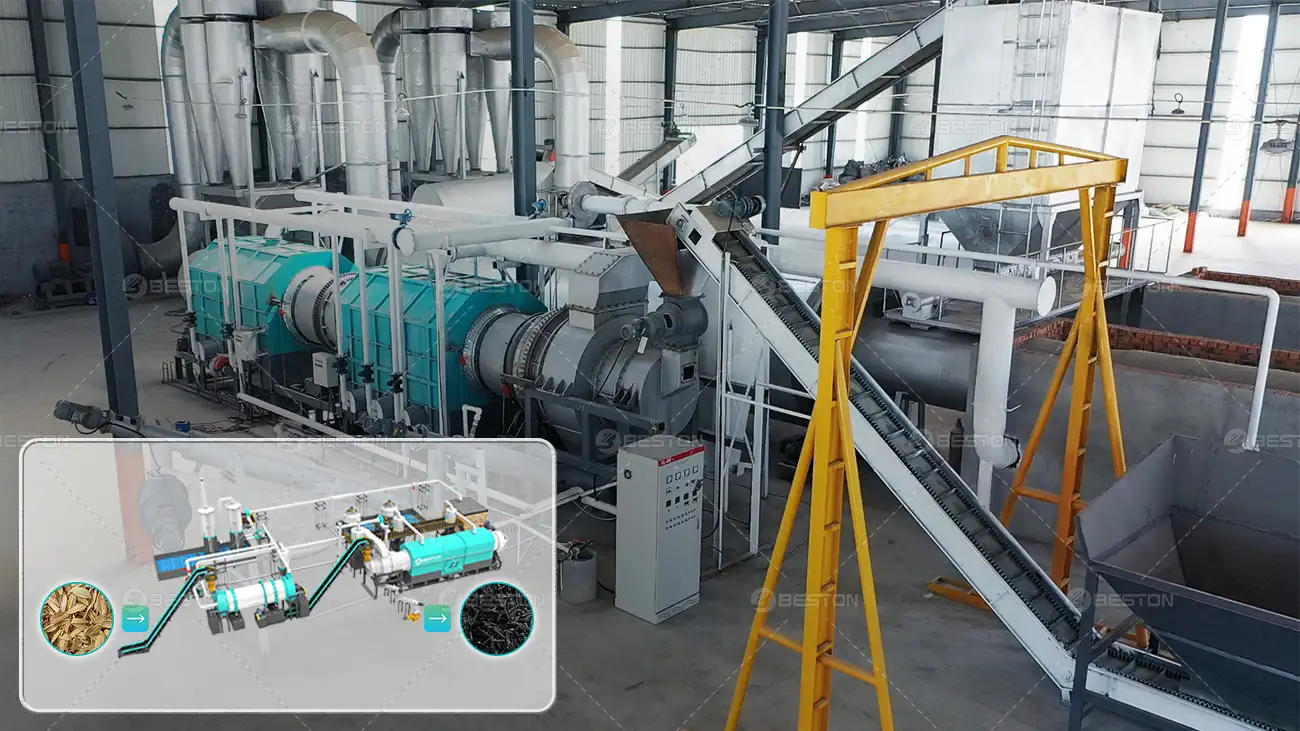

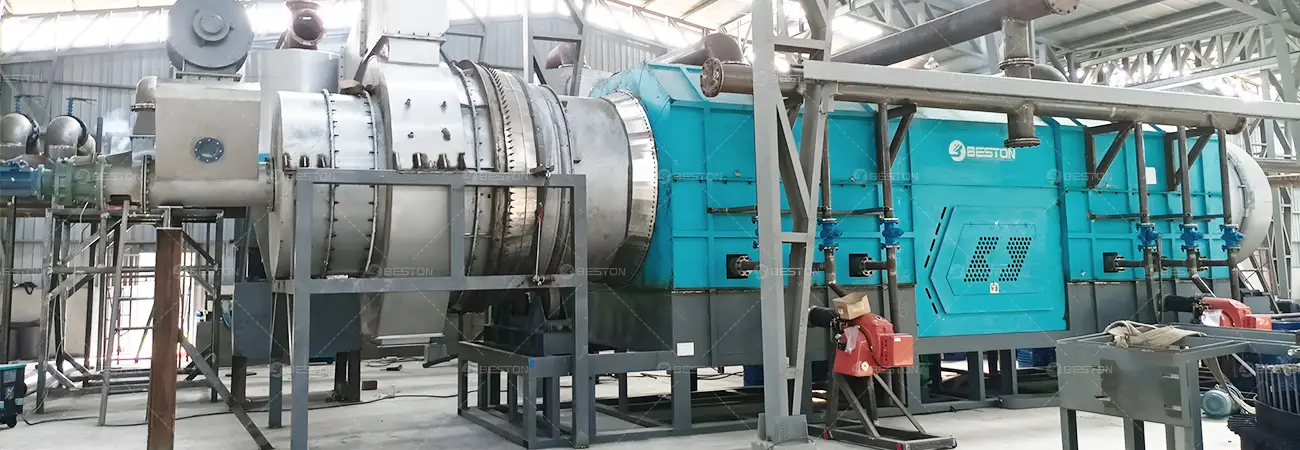

Reactor Design and Heat Transfer Efficiency

The design and configuration of the pyrolysis reactor are key to improving overall process efficiency. The reactor is the heart of the pyrolysis plant, where thermal decomposition occurs, and heat management must be optimized.

-

Temperature Control: Maintaining a consistent temperature throughout the reactor is crucial. The thermal breakdown of biomass into bio-oil, syngas, and biochar occurs at different temperature ranges. Typically, pyrolysis is carried out at temperatures between 450°C and 600°C. Effective temperature management ensures that each component is optimally converted without producing excessive char or uncondensed gases.

-

Heat Recovery: In many pyrolysis plant systems, the energy produced during pyrolysis can be partially recovered. For example, the syngas produced during the process can be used to fuel the reactor, reducing the need for external energy inputs. Efficient heat recovery not only lowers the plant’s energy consumption but also minimizes operational costs. Some advanced pyrolysis plants incorporate heat exchangers and other technologies to capture waste heat and redirect it for drying feedstock or pre-heating the reactor.

-

Continuous Processing: Continuous-feed biochar reactors as opposed to batch reactors, enable uninterrupted operation, which maximizes throughput and minimizes downtime. Continuous pyrolysis allows for a more stable thermal environment, improving reaction kinetics and ensuring that feedstock is consistently processed under optimal conditions.

Product Separation and Upgrading

To optimize the overall efficiency of a biochar pyrolysis machine, it is critical to effectively separate and upgrade the products. A pyrolysis process typically yields three major products: biochar, bio-oil, and syngas. Ensuring that each of these products is efficiently recovered and appropriately upgraded can enhance the economic value of the operation.

-

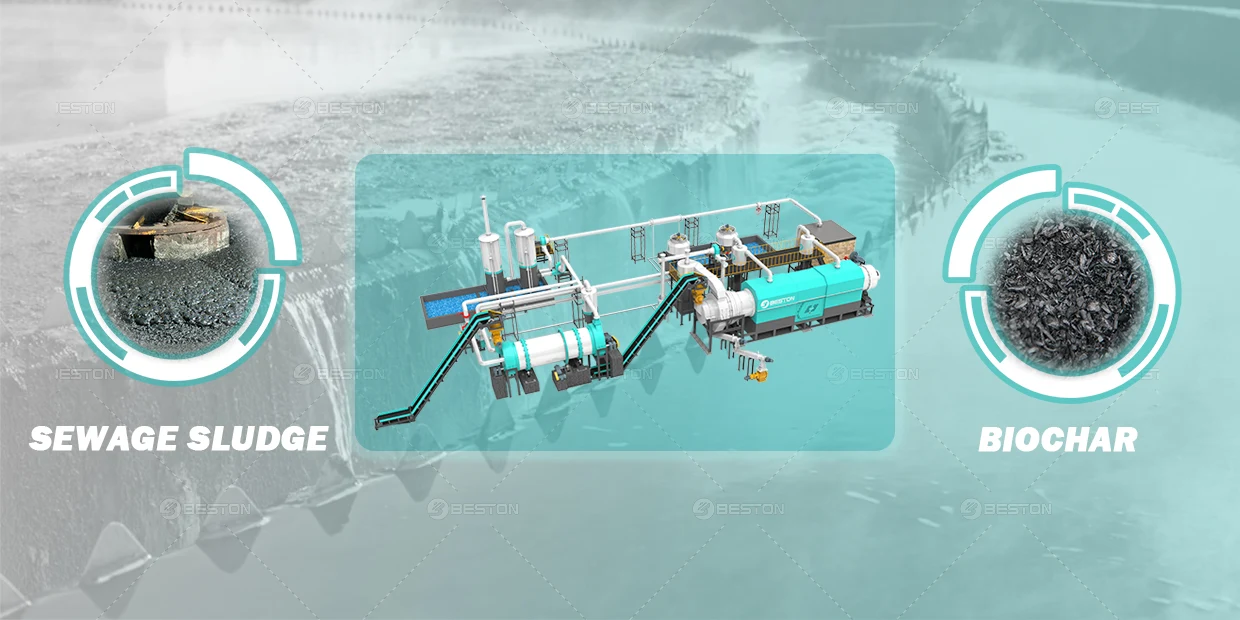

Biochar Handling: Biochar is a solid by-product that can be used in various applications, such as soil amendment, carbon sequestration, and industrial applications. The efficiency of biochar recovery depends on the design of the reactor and the retention time of the biomass. Minimizing the formation of residual ash and increasing the fixed carbon content of biochar improves its value.

-

Bio-Oil and Syngas Upgrading: Both bio-oil and syngas can be upgraded through catalytic processes to improve their fuel characteristics. Bio-oil, for instance, can be refined to remove water and impurities, improving its calorific value. Syngas, composed mainly of hydrogen, methane, and carbon monoxide, can be cleaned and used for electricity generation or as a chemical feedstock.

Automation and Process Monitoring

To further optimize the efficiency of a pyrolysis plant, incorporating advanced monitoring systems and automation can lead to improved process control. Automated systems can track key parameters such as temperature, pressure, and feedstock flow rate, allowing for real-time adjustments to ensure the system operates within its optimal parameters.

-

Real-Time Data: Monitoring systems can detect inconsistencies in the feedstock quality or reactor performance, enabling quick responses to prevent energy wastage or product quality issues. The ability to track and adjust parameters in real-time ensures that the pyrolysis process remains efficient and stable.

-

Control Systems: Advanced control systems can adjust the temperature and feedstock flow rates automatically based on the data received from sensors, optimizing the reaction conditions for maximum yield.